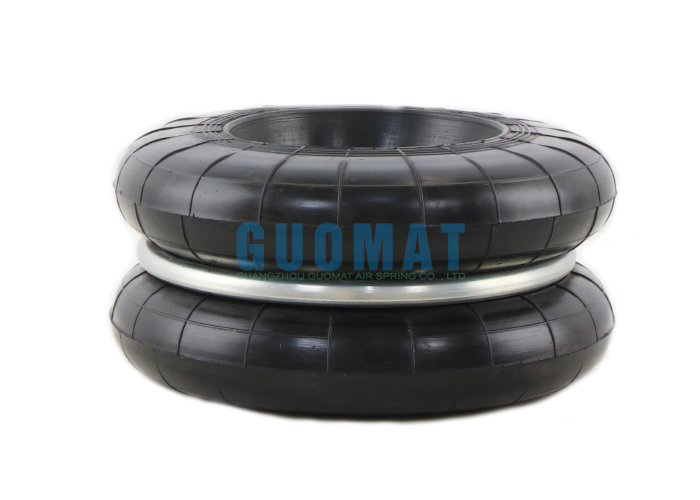

F-160-2 Dubbele airbags vervangende onderdelen S-160-2R Industriële luchtveer

OEM kruisverwijzing:

GUOMAT-deel nr.: F-160-2

De in de bijlage vermelde voorwaarden zijn van toepassing op:

De in de bijlage bij Verordening (EG) nr. 443/2009 genoemde voorschriften zijn van toepassing.

De in artikel 2 bedoelde maatregelen zijn in overeenstemming met de bepalingen van de overeenkomst.

Specificaties en gedetailleerde technische parameters

| F-160-4 |

F-160-3 |

F-160-2 |

| Kruis |

S-160-4 |

Kruis |

S-160-3 |

Kruis |

S-160-2 |

| Ontwerphoogte |

206 mm |

Ontwerphoogte |

152 mm |

Ontwerphoogte |

98 mm |

| Maximale hoogte |

306 mm |

Maximale hoogte |

227 mm |

Maximale hoogte |

148 mm |

| Min Hoogte |

111 mm |

Min Hoogte |

82 mm |

Min Hoogte |

53 mm |

| Maximale compressie buiten de diamater |

220 mm |

CompressieMaximaalBuiten Diamater |

220 mm |

CompressieMaximaalBuiten Diamater |

220 mm |

Luchtbronnen die worden gebruikt in perforatieapparatuur

In perforatieapparatuur zijn luchtveren (ook bekend als luchtkussens of pneumatische veren) een belangrijk hulpmiddel, dat voornamelijk wordt gebruikt voor buffering, schokdempering,krachtbalans of voorzien van verstelbare steun

1. Hoofdfuncties

Buffering en schokabsorptie: absorberen van de slagkracht tijdens het punchproces, verminderen van trillingen en geluid van de apparatuur, en beschermen van de vorm en machine-gereedschap structuur.

Beheersing van de krachtbalans: balans van het gewicht van de schuiver of de vorm om een soepele beweging te garanderen.

Drukregulatie: flexibele verandering van de grootte van de elastische kracht door de luchtdruk aan te passen aan verschillende tonnage- of procesvereisten.

Precieze slagregeling: handhaving van een stabiele neerwaartse druk of ejectie in precisie stempelen.

2Typische toepassingsscenario's

Vormbuffer: wordt onder de werkbank van de punchmachine geïnstalleerd en wordt gebruikt om het werkstuk uit te werpen of de rand te drukken (zoals bij het rekproces) om te voorkomen dat het materiaal rimpelt.

Schuifbalansysteem: zwaartekrachtcompensatie voor de schuif van de punchmachine (vooral grote persmachines) om de motorbelasting en mechanische slijtage te verminderen.

Trillingsisolatiesysteem: isolatie van de trillingsoverdracht van de perforatiescherm naar de fundering om de omringende apparatuur te beschermen.

3Voordelen en kenmerken

Verstelbaarheid: de luchtdrukregeling is flexibeler dan mechanische veren en kan zich aanpassen aan verschillende eisen aan de doorstekenkracht.

Lange levensduur: Geen mechanische wrijving, minder slijtage en een langere levensduur dan traditionele veren.

Energiebesparing en milieubescherming: in vergelijking met hydraulische systemen is er geen risico op olielekt en een lager energieverbruik.

Gemakkelijk onderhoud: eenvoudige structuur, lage storingsgraad, alleen de luchtcircuitverzegeling regelmatig moeten controleren.

4Voorzorgsmaatregelen

Afdichting: Controleer regelmatig het airbag- of zuigerdicht om te voorkomen dat luchtlekkages instabiele druk veroorzaken.

Aanpasbaarheid aan het milieu: vermijd dat hoge temperaturen, olie of scherpe voorwerpen de airbag beschadigen.

Veiligheidsredundantie: In hoge belastingsituaties van punchmachines wordt aanbevolen om meerdere luchtveren parallel aan te sluiten om een enkelpuntsfout te voorkomen.

Vaak gestelde vragen van gebruikers

V: Hoe lang is de levensduur van de airbag?

A: Ongeveer 3 tot 5 jaar bij normaal gebruik.

V: Hoe kan ik beoordelen of de airbag is uitgevallen?

A: Controleer wanneer de trilling van de punch toeneemt, de uitwerpsing onvoldoende is of de luchtdruk niet kan worden gehandhaafd.

V: Kan het de mechanische veer vervangen?

A: Ja, en het is gemakkelijker om het aan te passen, maar het heeft een stabiele luchtbron nodig.

Het echte beeld van de F-160-2 GUOMAT Press Air Spring

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!